Washing Systems

Showing 1–40 of 49 results

-

Terex H 25

Hopper Capacity:

20m3Motor / Gearbox Drive:

4kw (5hp) 189.3 ratioFeed Conveyor:

1050mm (42″) 3ply -

Terex H 20

Hopper Capacity:

20m3Motor / Gearbox Drive:

4kw (5hp) 189.3 ratioFeed Conveyor:

1050mm (42″) 3ply -

Terex H 9

Hopper Capacity:

20m3Motor / Gearbox Drive:

4kw (5hp) 189.3 ratioFeed Conveyor:

1050mm (42″) 3ply -

Terex PS 200 / PS 200R

Size of Tank:

7.5m (24' 7″) x 2.2m (7' 4″)No. of Paddles / Blades:

8 Paddles 152 BladesSize of Motors / Gearbox:

2 x 45kw (60hp) + on PS 200R 2 x 1.2kw 2 x 4.2kw -

Terex PS 120 / PS 120R

Size of Tank:

6m (20') x 2.3m (7' 7″)No. of Paddles / Blades:

8 Paddles/144 BladesSize of Motors / Gearbox:

2 x 22kw (30hp) + on PS 120R 2 x 1.2kw + 2 x 3kw -

Terex M 2100

Configuration:

2 Deck & 3 DeckScreen Size:

6m (20') x 1.5m (5')Engine Size:

83kw (111.3hp) std -

Terex M 1700

Configuration:

2 Deck & 3 DeckScreen Size:

4.9m (16') x 1.5m (5')Engine Size:

83kw (111.3hp) std -

Terex M 1400

Configuration:

2 DeckScreen Size:

3.7m (12') x 1.5m (5')Engine Size:

83kw (111.3hp) std -

Terex M 390

Configuration:

2 Deck & 3 DeckScreen Size:

3.7m (12') x 1.5m (5')Engine Size:

53kw (71hp) std -

Terex M 084

Configuration:

2 Deck and 3 DeckScreen Size:

2.4m (8') x 1.2m (4')Engine Size:

37kw (50hp) std -

Terex 206 ScreenBox

-

Terex 165 ScreenBox

Configuration:

4.9m (16')Screen Size:

1.5m(5')Engine Size:

18° – 22° -

Terex 125 ScreenBox

Configuration:

3.7m (12')Screen Size:

1.5m (5')Engine Size:

18° -22° -

Terex 084 ScreenBox

Configuration:

2.4m (8')Screen Size:

1.2m (4')Engine Size:

18° – 22° -

Terex Aggrescalp (no info)

Configuration:

Multiple ScreensNumber of Products:

5Water Requirement:

250m3 -

Terex AggreScrub 150 (no info)

Configuration:

Multiple ScreensNumber of Products:

5Water Requirement:

250m3 -

Terex Aggresand 206 (no info)

Configuration:

Multiple ScreensNumber of Products:

5Water Requirement:

250m3 -

Terex Aggwash 300 (no info)

Configuration:

Multiple ScreensNumber of Products:

5Water Requirement:

250m3 -

Terex AggreSand 165

Configuration:

Multiple ScreensNumber of Products:

5Water Requirement:

250m3 -

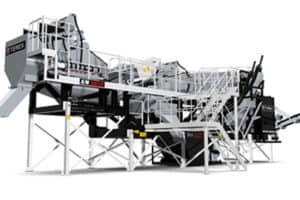

Terex Aggwash 60-1 / 60-2

Configuration:

Multiple ScreensNumber of Products:

6Water Requirement:

100 – 190 m3 per hour -

Terex Clarified Water Tanks

TWS offer a complete tailored solution for water treatment and management, Terex Washing Systems provides a complete range of filter presses, flocculent dosing systems and thickening tanks.

-

Terex Thickener Tanks

TWS offer a complete tailored solution for water treatment and management, Terex Washing Systems provides a complete range of filter presses, flocculent dosing systems and thickening tanks.

-

Terex Filter Press

TWS offer a complete tailored solution for water treatment and management, Terex Washing Systems provides a complete range of filter presses, flocculent dosing systems and thickening tanks.