Multiple Screens

5

250m3

Description

Overview

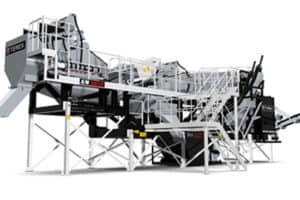

3 Aggregates, 2 Sand, 1 Machine – The AggreSand

Terex® AggreSand system combines aggregate washing and screening with sand processing on a modular chassis. It brings together tried and trusted Terex Washing Systems components in an innovative modular design, setting itself apart from other washing systems in the marketplace.

Features

Key Features & Benefits

• 3 Aggregates, 2 Sand, 1 Machine

• Fully Modular

• Fully Automated

• Radio Controlled

• Containerised Transport

• Pre Wired & Pre Plumbed

• 1 Day Set-Up

• 1 Electrical Connection Point

• 1 Water Connection Point

• Curved Chassis

• Gaps in chassis for wash down

Applications

• Virgin Aggregate

• Manufactured Sand

• Sand & Gravel

• Crushed Rock

• Crusher dust

• Scalpings

• Iron ore

• Other mineral ores

• Construction & Demolition Waste Material

Dewatering Screen

• 2 or 3 deck Screen box option

• Electrically driven

• Fixed 18 degree working angle

• Spring mounted

• Enclosed rubber lined wash box c/w independently controlled spray bar

• 8 independently controlled isolated spray bars per deck complete with fan tail plastic nozzles

• Polyurethane modular decks as standard (mesh deck option)

• Lined rolling chute arrangement complete with blending capabilities

• Rubber lined catch box (c/w 1/3-2/3 rubber lined division plate for dual sand models)

• Rubber lined discharge chutes

• Pressure clock on manifold

• Inspection flaps to view screen media

Centre Chassis

• Rubber lined slurry pump(s) situated upon roll out maintenance platforms

• Ceramic lined bends

• One point water feed

• Pre-wired control panel with external HMI panel

• Large volume sump tank

• Plant wash down reel

• Sump Tank

• Split tank for double grade (double grade only)

• Float on coarse side of tank (double grade only)

• Letterbox on divider plate to keep tank levels equal (double grade only)

• Overflow box

• Large inspection doors (both sides on double grade)

• Tank drain (both sides on double grade)

• Anti-turbulence baffle plates

• Replaceable rubber lined wear plates on feed area

Sand Plant

• High energy 3.7m x1.5m (12’x5’) Dewatering screen – dewatering up to 120TPH of sand

• Polyurethane modules and side protection bars

• Moulded central division plate (double grade only)

• Rubber lined cyclones

• Ceramic lined inlet bends

• Rubber lined underflow boxes – c/w quick release lid

• Rubber lined blending box – c/w quick release lid (double grade only)

• 5.5m (18’) dirty water discharge height

• Rubber lined catch box for screen underflow

• Spray bar in catch box

• Polyethylene wear board in discharge chute

• Adjustable discharge blending chute – double grade only

• Pressure gauge to monitor cyclone inlet pressure

• High specification cyclone inlet hoses c/w flanges

Radial Conveyors

AGGREGATE CONVEYORS

· Rigid – folded for transport

· Plain 26” (660mm) wide belt

· 18 degree angle

· SCS tear drop scraper (option)

· Direct drive electric gearbox

· 9.3m (30′ 5″) long

· 4.1m (13′ 5″)discharge height

· 3 deck oversize conveyor can discharge to right or left side

SAND CONVEYORS

· Rigid – folded for transport

· Radial – skid mounted as standard

· Radial – wheel drive option

· Plain 26” (660mm) wide belt

· 20 degree angle

· SCS tear drop scraper (option)

· Direct drive electric gearbox

· 9.3m (30′ 5″) long

· 4.9m (16′ 1″) discharge height

Cutting Edge Control panel

• Robust full color graphic HMI (Human Machine Interface)

• Automated Start / Stop sequence of all plant items

• Automated sequence shutdown on fault detection

• On-screen display of all key Parameters inc:

– Inlet water Flow

– Cyclone pressure

– Hydraulic oil level and temperature

– All motors load currents and voltages

• Radio control of

– Plant Start / Stop

– Feeder Start / Stop

– Sand Conveyor Radial Drive

– Tipping Grid Raise / Lower

– Plant Lighting On / Off

Options

• Telemetry System with remote communication of all alarms and status such as TPH via text message

Walkways

• Galvanised

• Walkway round both sides of machine

• Expanded metal walkway floors

• Curved ends on handrails

• 600mm (24′) wide

Options

• High capacity sand option (200tph)

• Single sand

• 2 deck