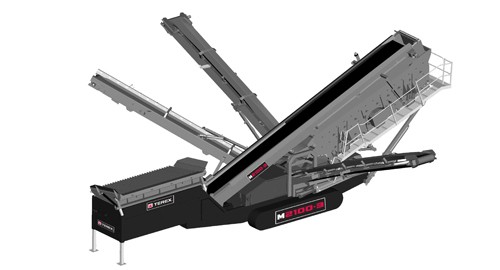

2 Deck & 3 Deck

6m (20') x 1.5m (5')

83kw (111.3hp) std

Description

Overview

The Terex® M 2100 Washplant is designed for medium to large scale operations that require large volumes of high specification products. With on board side conveyors, the M 2100 Washplant can produce up to 5 end products in applications including coal, iron ore, crushed stone, recycled materials, sand and gravel. Additional features include class leading stockpile discharge heights and hydraulic screen angle adjustment

Specifications

| TRACK (2 DECK) TRACK (3 DECK) | |

| Weight (Est.) | 37,700kgs 37,200kgs (76,500lbs) (82,012lbs) |

| Transport Width | 3m (9’10”) 3m (9’10”) |

| Transport Length | 18m (59’1”) 18m (59’1”) |

| Transport Height | 3.32m (10’11”) 3.45m (11’4”) |

| Working Width | 18.25m (59’10”) 18.25 (59’10”) |

| Working Length | 19.25m (63’1”) 18.63m (61’1”) |

| Working Height | 6.67m (21’11”) 6.67m (21’) |

Features & Benefits

• High capacity (depending on mesh sizes and material type)

• Quick set up time typically under 15 minutes

• Excellent mobility with heavy duty, low ground pressure crawler tracks

• Optional tri-axle bogie system allows the track machine to be transported without the need for a low loader

• Removable heavy duty pendant remote control system

• Optional radio control system available if required at extra cost

• High performance hydraulic system

• Angle adjustable tipping grid with radio control double acting tipping grid rams

• Low profile single and double deck vibrating grid option with remote control tipping. Angle adjustable and fully riveted construction

Options

• 12ft 2 deck vibrating grid

• Extended re-circulation oversize auxiliary conveyor

• Dual power (can be operated electrically)

• Quick release wedge screen tensioning

• Bonded rubber wearplate in washbox

• Sealed pipes with bonded rubber lining

• 18’ x 5’ single or twin grade catchbox

• Rubber screens

• Roll-in bogie prepared

• Roll-in bogie equipped

• Radio control tracks

• Prepared TUV chassis

• Auto lubrication system

• Hydraulic screen tensioning

• Dry screen tail conveyor

• Single or Double deck vibrating grizzly

• Single shaft, flail type shredder

• Wheel bogie for track machine

• Hydraulic jacking legs