| Key specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Total weight | 39710 kg | ||||||||

| Max permitted power | 500 kW | ||||||||

| Capacity | 214-1024 mtph | ||||||||

| CSS range | 13-51 mm | ||||||||

| Max feed size | 275 mm |

Description

Sandvik CH860 and Sandvik CH865 are technologically advanced, mid-range cone crushers designed for your mine’s specific requirements. With a more than two-fold increase in performance range compared to other crushers in their class, Sandvik CH860 and Sandvik CH865 offer production flexibility. Depending on crushing application, they perform up to 30% better.

Sandvik CH860 is dedicated for high capacity secondary crushing thanks to its 500kW motor delivering higher power and more crushing force at maximum throw. The aggressive crushing action processes more ore, yet maintains product size, giving customers more throughput.

Each crusher is supplied as a complete package with all functions working in harmony and with a motor designed for exacting requirements. The Automatic Setting Regulation – ASRi™ control system enables real-time performance management, most tangibly equaling maximized crusher performance and productivity.

Features and benefits

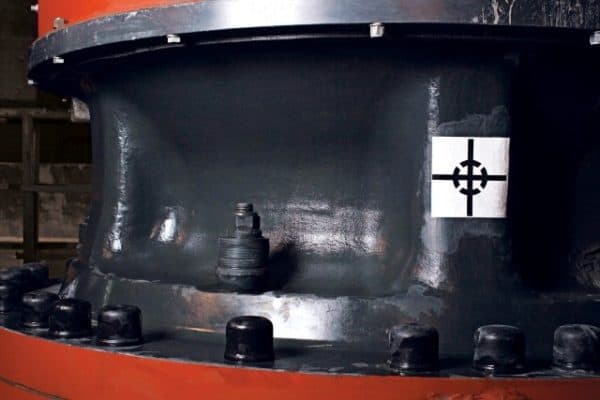

- Hydroset™ system provides safety and setting-adjustment functions

- ASRi™ automatically adapts crusher to feed conditions

- Unibody mainframe ensures optimal strength and less maintenance

- Lifting from above minimizes risks and allows for safer maintenance

- PLC-controlled electric dump valve for tramp iron protection

Several standard crushing chambers are available for each model. The crushers can easily be matched to changes in production selecting the right crushing chamber and eccentric throw. The chambers available are:

M = Medium

MC = Medium coarse

C = Coarse

EC = Extra coarse