28

10,637L (2,340gls)

2

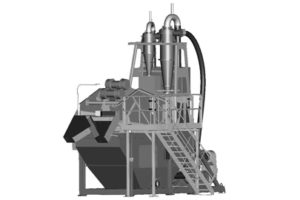

Description

Overview

• Mobile bucket wheel dewaterer complete with retention screw screw

• Can produce up to 2 grades of sand

• Designed to operate with maximum versatility and can support different requirements such as maximum retention of fines or maximum disposal of fines

• Can be driven hydraulically from the M Range or from its own optional electric power pack

Specifications

| Wheel Diameter | 2.75m (9’) |

| Spiral Diameter | 2.04m (6’ 9”) |

| Spiral Length | 3.10m (10’ 2”) |

| Weir Length | 40m (131’ 2”) |

| Bucket Width | 0.75m (30”) |

| No. Buckets | 28 off |

| Water Tank Capacity | 10,637L (2,340gls) |

| Water Flow Rate | 2270-5000L/m (500-1100Gpm) |

| Working Length | 6.8m (22’ 5”) |

| Working Width | 4.4m (14’ 3”) |

| Working Height | 3.7m (12’) |

| Total Weight Working | 14800kg (32600lb) |

Features & Benefits

• Double & single grade chutes (plastic lined)

• Slurry intake boxes (rubber lined)

• High capacity variable speed twin bucket wheel

• Deep fluted fines recovery screw with variable speed

• 15 HP electric / hydraulic powerunit (optional)

• Adjustable plate between bucket and settling tank for release or retention of fines

• 6 point water injection system for agitation and floating off fines where necessary

• High capacity 100-150mtph (110 – 165ustph) depending on material size and type

• Low running cost

• Can produce one or two grades of material

• Excellent fines recovery

• Specially designed inlet boxes which reduce turbulence at entry.

• Weir discharge system adjustable from 0 – 40m (131ft) long.

• Production of silt free material

• Increased drainage time produces a drier product

• Can be hydraulically coupled to TWS Mobile M Range

• Breaks down into one 40” (12m) container

• Double & single grade chutes (plastic lined)

• Slurry intake boxes (rubber lined)

• High capacity variable speed twin bucket wheel

• Deep fluted fines recovery screw with variable speed

• 15 HP electric / hydraulic powerunit (optional)

• Adjustable plate between bucket and settling tank for release or retention of fines

• 6 point water injection system for agitation and floating off fines where necessary

• High capacity 100-150mtph (110 – 165ustph) depending on material size and type

• Low running cost

• Can produce one or two grades of material

• Excellent fines recovery

• Specially designed inlet boxes which reduce turbulence at entry.

• Weir discharge system adjustable from 0 – 40m (131ft) long.

• Production of silt free material

• Increased drainage time produces a drier product

• Can be hydraulically coupled to TWS Mobile M Range

• Breaks down into one 40” (12m) container

Options

• Boiler box for dry feed

• Electric hydraulic powerpack

• Static unit without towbar and wheels

• No water injection system