2 Deck & 3 Deck

3.7m (12') x 1.5m (5')

53kw (71hp) std

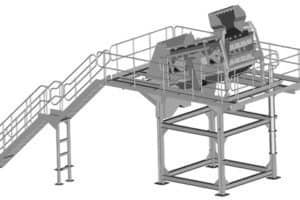

Description

Overview

The Terex® M 390 Washplant is a high capacity mobile washing unit that has been engineered for quick installation and ease of relocation making it ideal for applications including sand, gravel, coal and crushed stone. The M 390 Rinser includes a feed hopper complete with reject grid, feed conveyor, washing screen, fully enclosed power unit, twin break and suspended axles, hydraulic jacking legs, king pin towing facility and site drawbar

Specifications

| Working Width | 2.50m (8’ 2”) |

| Working Length | 20.37m (66’10”) |

| Working Height | 6.25m (20’ 6”) |

| Transport Width | 2.5m (8’2”) |

| Transport Length | 12.9m (42’4”) |

| Transport Height | 4.35m (14’3”) |

| Weight | 17,500kgs (38,500lbs) |

Features

Features & Benefits

• Deutz air-cooled engine (71hp/53kW)

• 1 x T 150 / T 200 and 2 x T 5032 stockpiler drive facility (NOT Standard on Electric/Hydraulic Machines)

• 1050mm wide variable speed belt feeder (no deflector doors fitted)

• 8.0m hopper (10.5cu. yards) -14’

• 100mm remote control hydraulic tipping reject grid 4.25m (14’) complete with grouser bars

• 3.7m x 1.5m (12’ x 5’) double deck washing screen

(12’ x 5’ on both decks)

• Washbox complete with 5 adjustable water jets at main conveyor discharge

• Total 17 washing spray bars fitted to both decks

• Screen box reject chutes lined with replaceable steel liners

• Sand water collection hopper (single product) complete with 6m standard open troughing

• 1m (3’3”) wide main belt

• Polyurethane teardrop profile belt scraper fitted at drive drum

• Skirting on main conveyor & steel water supply pipe up one side

• Twin braked and suspended axles

• Hydraulic jacking legs, King pin towing facility & site drawbar

• Guards designed to comply with Machinery Directive

• Rated @ 2 bar pressure at spray nozzles

• 2 deck machine can be transported Ro-Ro. 3 deck machine requires the screenbox to be transported seperately

Options

• Electric/hydraulic drive – (37kW) (No coupling facility) (not including electric control panel)

• Electric/hydraulic drive – (37kW + 18.5kW) complete with

1 x T 150 / T 200, 2 x TC 5032 stockpiler drive facility (not including electric control panel)

• Deutz Water Cooled Engine (100hp/75kW) complete with x T 150 / T 200 and 4 x stockpiler drive facility

• No grid but hopper deadplate fitted

• 4” double deck vibrating grid complete with abrasion resistant plate on wear surface of T Bars top deck and mesh in bottom deck and Deutz water cooled engine (100hp/75kW)

• 20mm thick rubber lining of standard stone chute (price per deck)

• 6mm thick rubber lined sand box (single product)

• Side tensioned rubber mats top deck of screen

• End tensioned rubber mats bottom deck of screen

• End tensioned rubber mats middle deck of screen (3 deck only)

• Hydraulic tensioning (bottom deck screen mesh)